ASPL also offers consulting and study services in industrial process engineering, which is usually provided after the R&D, process, and product development.

Our offer includes audits, technical studies, consulting, and R&D services. We combine our expertise in industrial process engineering with our software and methodologies to offer you the most efficient and economical solutions.

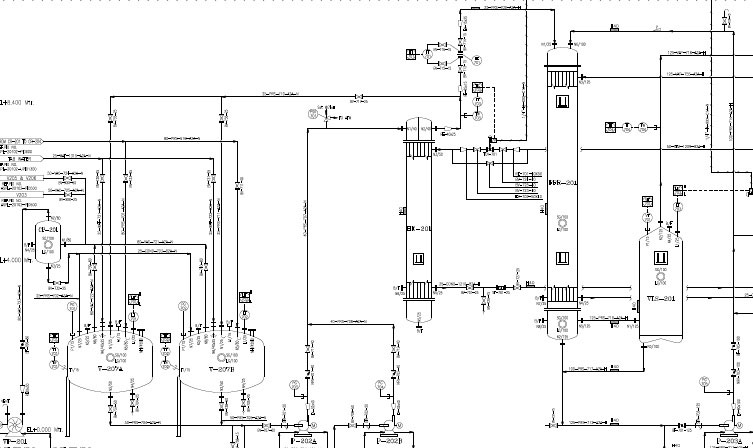

Build a new factory or a pilot plant, develop a new process or a new piping network, and improve existing ones? We offer you our expertise in process engineering at each stage of the life cycle of your project.

With ASPL, benefit from independent and experienced consultants. Our experts are at your service to analyze, design, and optimize your processes and fluid flow networks in a wide range of industries and applications.

ASPL works closely with you from start to finish to make your project a reality. Please be confident; our team has completed many successful engineering projects all over the world.

Our team of experts manages the improvement of the performance of your installations and adapts them to new constraints or operating conditions.

Combining science and industrial pragmatism, we take advantage of our process simulation software. We use modeling and simulation to improve the efficiency and profitability of your processes. With us, you can:

ASPL offers this array of process consultancy capabilities combined with such a wealth of process engineering expertise after the completion of R&D, process, and product development. Whether you require consulting or construction management, process design, equipment or automation, layout or emission reduction services for an existing or newly built plant, our team provides in-depth expertise in consulting and engineering in all sectors.

Our customers around the world choose to work with us at their many locations because we understand their unique challenges and are able to design solutions to reduce and transform waste, improve production efficiency, optimize assets and increase value throughout the life cycle of the project.

ASPL has extensive knowledge of industrial processes and facilities in all industries. We offer a full range of required services, from conducting feasibility studies to designing and constructing factories.

Developing Comprehensive & Integrating process Systems by Extraction Method

This phase include the knowing of Requirement and Specification.

Feasibility Analysis:

The feasibility study comprises basic analysis of the systems integration project.

Architecture and Development:

In this development process get started based on the requirement.

Management Plan:

Once the development process get complete, management plan follows next.

Implementation:

Once the systems design is ready, it is verified and implemented thoroughly.

Evaluation:

This is the last phase where the functioning of the integrated systems is checked thoroughly. The evaluation phase comprises checking, maintaining, adjust and enhancing the components.

Product Consultancy Services